Choosing the right production machinery is a crucial step for any business. The equipment you select impacts efficiency, product quality, and your bottom line. Whether you’re a startup or an established company, making the right choice can save you time and money in the long run.

In this blog post, we’ll share some helpful tips to guide you in selecting the best production machinery for your needs. By following these tips, you can ensure your business runs smoothly and remains competitive in today’s market. Read on and learn more.

Understand Your Business Needs

Before you begin searching for production machinery, you must first understand your business needs. What products will you be making? How large is your production scale? These questions will help determine the type of machinery needed.

Consider your production goals. Are you focused on efficiency, speed, or flexibility? Understanding your priorities will guide you in choosing the most suitable manufacturing machine.

Finally, take into account your future growth. Will the machinery you choose be able to handle an increase in production if needed? It’s always wise to think long-term.

Consider the Type of Product You Are Making

The type of product you are making will influence the machinery you need. Some machines are designed for specific products, while others are more versatile. Be sure to choose machinery that matches the characteristics of the product you want to produce.

For example, gummy bear manufacturing equipment is ideal for candy makers. You might need specialized machines for precise temperature control or hygienic production standards. Consider whether your product requires high customization or simple mass production.

Also, assess whether your product requires any special features in the equipment, like packaging or labeling capabilities. The right machinery will fit seamlessly into your production process.

Research the Machinery’s Features

Different machines come with different features. It is important to research these features before making a decision. Look for machines that offer the capabilities your business needs to stay competitive.

For example, if you are in the food industry, you may want equipment with features like temperature control, automated mixing, or specific molds. Some machines might offer energy-saving features that can help reduce costs in the long run.

You should also consider the user interface. Is it easy for your team to operate? Simple, intuitive controls can save time and reduce the need for extensive training.

Look for Durability and Reliability

You want production machinery that is built to last. Durability is important because you don’t want to face frequent breakdowns or need costly repairs. Check the materials and construction of the machinery.

Ask the manufacturer about the machine’s expected lifespan. Quality machines may cost more upfront, but they can save you money over time by reducing maintenance costs and downtime.

Reliability is also key. Look for machines that have a good track record in your industry. Reading reviews or talking to other businesses can help you find machinery that you can trust to perform well over time.

Evaluate the Cost

Cost is an important factor when choosing production machinery. While it’s tempting to go for the cheapest option, keep in mind that the lowest price might not always be the best value. Consider your budget but also think about long-term savings.

Buying machinery is an investment. Look for equipment that balances price and performance. Sometimes, paying a bit more upfront can lead to fewer repairs, better performance, and longer service life.

Also, consider the cost of maintenance, parts, and energy use. These ongoing costs will affect your bottom line over time.

Assess the Speed and Efficiency

Speed and efficiency are crucial for most businesses. Choose production machinery that can handle your required output. You don’t want to fall behind schedule due to slow equipment.

However, speed isn’t everything. Efficiency also matters. A machine that runs at high speed but wastes energy or produces low-quality products isn’t a good investment.

Look for equipment that can provide the right balance of speed, efficiency, and quality. Efficiency is about getting the most out of your equipment while minimizing waste and costs.

Think About Space and Layout

The space you have available is an important factor when choosing machinery. Industrial machinery can take up a lot of room. Make sure you have enough space for the equipment you want.

The layout of your production area is another consideration. Will the machinery fit into your existing setup? Will it be easy to integrate into your workflow without causing disruptions?

Measure the space carefully before purchasing. You may need to rearrange your floor plan or even expand your facility to accommodate new machinery.

Consider Energy Efficiency

Energy-efficient machinery can help you save money in the long run. Machines that use less energy reduce your utility bills and can also help your business reduce its carbon footprint.

Check the energy rating of the machines you are considering. Machines with higher efficiency are often designed to minimize energy waste during production.

If energy consumption is a concern, you can also explore machines that run on alternative energy sources, like solar power. While they may require higher upfront costs, they can lead to significant savings over time.

Check for Ease of Maintenance

All machinery requires maintenance at some point. It’s important to choose equipment that is easy to maintain. Machines that require complex or costly repairs will drain your resources.

Look for machines that have easy access to parts and components. A machine that is easy to maintain will keep your production line running smoothly without frequent interruptions.

You should also consider the availability of spare parts. Machines with a wide range of available parts are easier to repair and service.

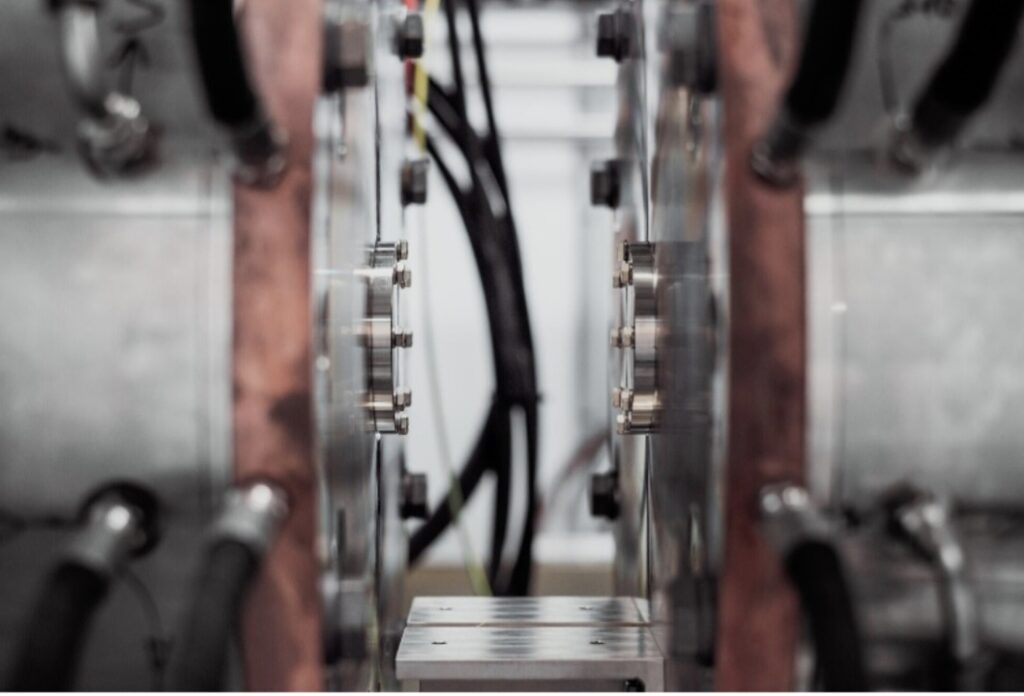

Understand the Technology Used

The technology behind production machinery can vary greatly. Some machines use advanced technology like automation, sensors, and data analytics to improve performance.

Consider whether these technologies are important for your business. Automation can increase production speed, while sensors can ensure product quality.

However, advanced technology often comes at a higher cost. Weigh the benefits of these technologies against your budget and production needs to make the right choice.

Consider the Brand’s Reputation

The reputation of the equipment manufacturer matters. Choose machinery from well-known brands with a good track record. A reputable brand is more likely to provide high-quality, reliable equipment.

Research the brand’s history and customer reviews. Positive feedback from other businesses in your industry is a good indicator of the brand’s quality and customer service.

Also, check if the brand offers support and warranty options. A company with strong after-sales support can help you resolve issues quickly if something goes wrong.

Look for Customization Options

Some businesses require customized production machinery to meet specific needs. If this applies to your business, look for manufacturers that offer customization options.

Customization allows you to tailor machinery to your exact specifications. Whether you need specific molds, unique features, or different material handling capabilities, customization ensures that the machine fits your business perfectly.

However, customization can increase the cost and lead time for delivery. Make sure the benefits of a customized machine outweigh the added expenses and time.

Think About Safety Features

Safety should always be a priority in any production facility. Look for machinery that comes with built-in safety features to protect workers and reduce the risk of accidents.

Many modern machines include safety mechanisms like emergency stop buttons, safety shields, and automatic shut-off systems. These features help keep workers safe and reduce the chances of machine malfunctions causing harm.

Also, ensure that the machine complies with local safety regulations and standards. Machines that meet industry safety standards help you avoid potential legal issues and ensure a safe working environment.

Test the Machinery Before Buying

Whenever possible, try to test the machinery before making a purchase. Many equipment manufacturers offer demos or trials, allowing you to see the machine in action.

Testing the equipment gives you a better idea of its performance. You can assess its speed, efficiency, ease of use, and overall quality before making a final decision.

If testing isn’t possible, ask for a video demonstration or visit a company that uses the same machinery. Seeing the machine in action helps you make an informed choice.

Get Expert Advice

Choosing production machinery can be complex. If you’re unsure, seek advice from experts in the field. Consult with equipment manufacturers, industry professionals, or business consultants who specialize in machinery selection.

Expert advice can help you make a more informed decision. They can guide you in understanding the features you need and suggest machines that match your production goals.

Also, consider speaking with other business owners in your industry. Their experiences can provide valuable insights into the types of machinery that work best for specific products and production processes.

Maximizing Efficiency Through Smart Production Machinery Choices

Choosing the right production machinery is key to your business’s success. It helps you save time, reduce costs, and improve product quality. Take your time to research, compare options, and consider your specific needs.

The right equipment will fit your goals and grow with your business. Remember, investing in good production machinery now will pay off in the future. Make sure to choose wisely to keep your business efficient and competitive.

Did this article help you? If so, take a look at some of our other blog posts for more informative reads.